How to repair and protect magnetic polishing machine?

Repairing magnetic polishing machine

1: polishing bucket leaking, the bottom thorn has polished needle, can be removed by pliers, add a little glue

2: timer does not blink, did not press the start switch, press it to time.

3: polish the water in the barrel. Please change the water as soon as possible. (the normal temperature range is 50 C).

The 4: machine makes a big splash and checks whether each corner of the machine is in force direction and adjusts its length.

5: instructions normal, but the machine does not work, to see whether the voltage is less than 220V; polishing needle placement is not excessive?.

Peacetime maintenance

1: polishing liquid splashed on the machine should be promptly scrubbed clean, to avoid liquid damage to the appearance of the machine.

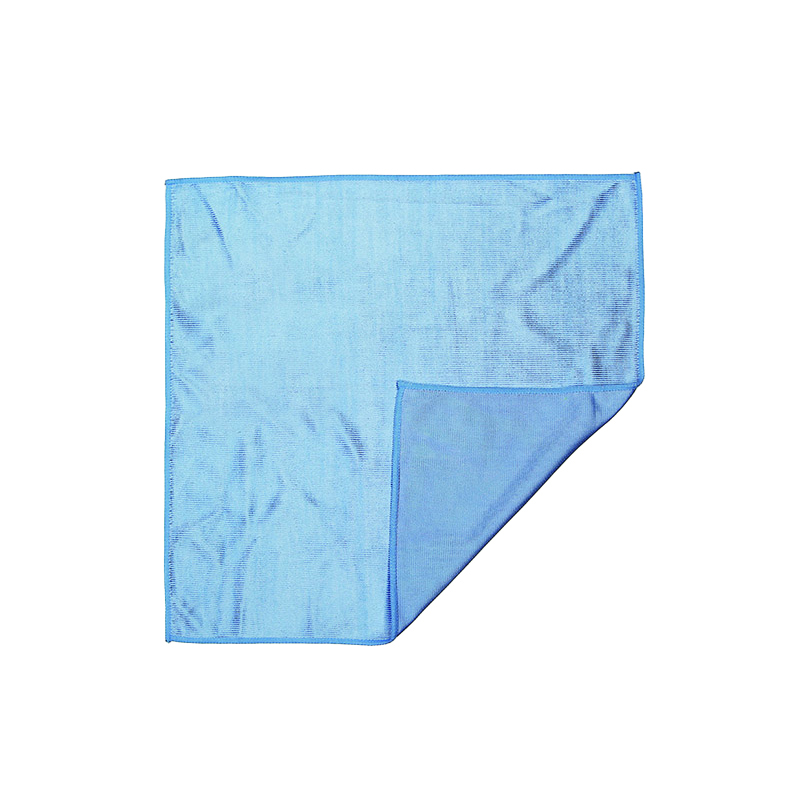

2: after using the cloth to clean the machine surface

3: when not in use, the control panel is covered with plastic bags, so dustproof and antifouling can be used.

4: bucket, polishing groove if there is polished needle, should promptly clean up.

Recommend

Industry News

- What is the key to polishing ma

- Use and maintenance of pneumati

- Safe operation process of polis

- Polishing machine manipulation

- Polishing machine construction

- How does a pneumatic polisher p

- The use of cylindrical polishin

- Polishing machine introduction

- How to repair and protect magne

- What are the features and featu